Attract More Sales With Embossing and Debossing

Embossing and debossing are the two advanced finishing techniques that bring texture and visual appeal to the packaging materials. Being similar in process, these methods offer quite different results. Today, in the competitive landscape of packaging industries, brands highly use these methods to engage people. Unique Custom Packaging, one of the most trusted packaging brands, offers these finishes at notable prices. Contact now and upscale your sales shortly.

Embossing and Debossing: A Short Overview

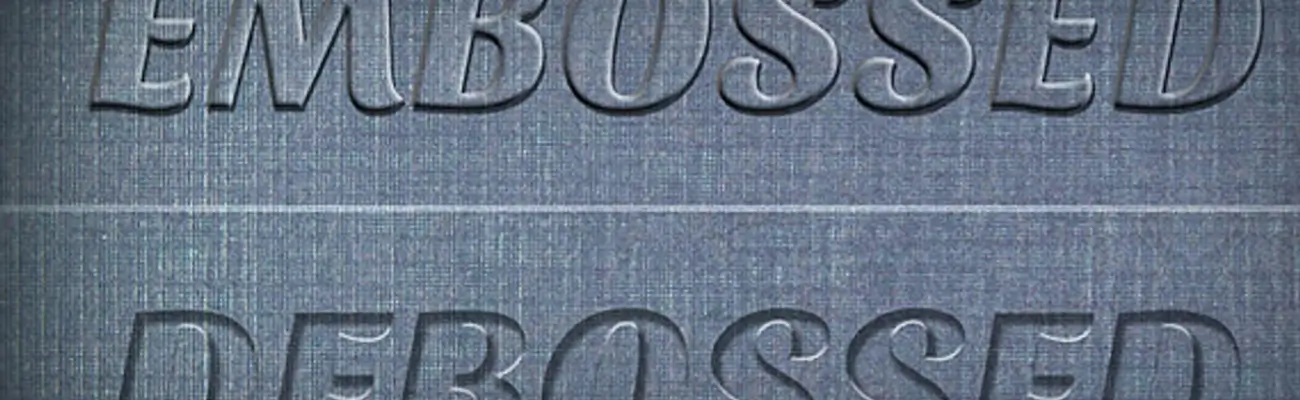

Embossing is the latest technique for creating a raised pattern or picture on packaging material. It is best applied to paper or cardstock. A custom-made die (a metal plate) is pressed into the reverse side of the material, making the design rise above the surface. This 3D effect not only adds a tactile element but also makes the embossed area more prominent.

Debossing is contrary to Embossing. Instead of creating a raised pattern, it forms an indented impression. During this process, the packaging material is pressed down from the top, offering the design a subtle yet classy look. The depressed area provides a unique shadow that is both visible and touchable.

Explore the Major Differences Between Embossing and Debossing

- No doubt, both these techniques are preferred by brands. The following are some of the significant differences that help brands make informed decisions:

- Embossing forms a raised design, while debossing sinks the design into the material.

- Embossing is ideally used with finer details. Meanwhile, debossing offers a more minimalist and modern design look.

- Embossed designs are more visible in contrast to the debossed designs.

- Embossing is often used for stationery and business cards. Debossing is typically applied to leather goods, like wallets and portfolios.

- Embossing might stretch or wrap the materials, while debossing compresses the materials.

What are the Famous Uses of Embossing Finish and Debossing Finish?

These techniques are immensely popular among different industries. Embossing, adding a luxurious touch, is highly famous in the stationery and printing industry. Whereas the leather goods industry preferably picks debossing. The uses of both these methods are shared below:

Uses of Embossing

The following are some of the known uses of embossing in the market:

- Embossed business cards typically stand out in the market and appeal more visually.

- Wedding and other invitation cards are often designed with embossing for a graceful appearance.

- The packaging industry prefers embossing to highlight a brand’s logo, name, tagline, contact details, and other vital textual data.

- Personalized stationery is usually embossed with initials or tailored motifs.

- Embossing is widely used to create decorative patterns or titles on book covers.

Uses of Debossing

It is equally versatile and is known for some of the following uses in the market:

- Debossing is commonly used on leather items, like wallets and belts, to imprint logos or designs.

- Promotional items, such as silicone wristbands and keychains, are usually debossed with a brand’s name or slogan.

- Like Embossing, debossing can also boost the visual appeal of packaging boxes. It is highly used for luxury items.

- Debossed note cards and letterheads, offering a high-end feel, are also available in the market.

- Consider the material, desired effect, and overall design when choosing between these two finishing methods.

Choose Unique Custom Packaging!

Want to boost the visual appeal of your product’s Packaging? Choose Unique Custom Packaging, one of the trusted names that offers top-notch customized boxes. Whether you want to emboss or need debossing to stand out your Packaging on the store’s shelves, we offer both at competitive rates.

Finishing Options That We Provide:

“Contact us now and avail yourself of our expert services to boost your brand’s sake immediately.”

Get Custom Quote

Shop with Confidence

Money Back Guarantee